American Manufacturing in a Global Market

The Future of American Manufacturing: Can It Compete Globally?

Estimated reading time: 6 minutes

- Understanding the impact of globalization on American manufacturing.

- Leveraging AI and workflow automation to enhance efficiency.

- Addressing workforce challenges through skill development.

- Improving recruitment strategies using AI consulting.

- Focusing on sustainability and eco-friendly practices.

Table of Contents

Understanding the Current Landscape of American Manufacturing

Historically, the United States has been a leader in manufacturing, contributing significantly to the economy and providing millions of jobs. However, recent trends indicate a shift, as companies increasingly look toward global markets for both production and consumption. Manufacturing in America faces challenges such as:

- Increased Global Competition: Countries such as China, India, and Vietnam offer lower labor costs, leading many companies to outsource production, which in turn impacts domestic jobs and economic growth.

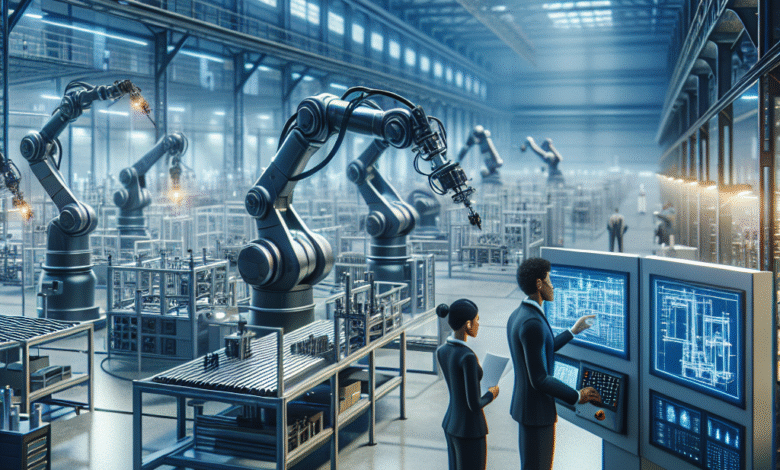

- Technological Disruption: Automation, robotics, and the Internet of Things (IoT) are revolutionizing manufacturing processes. While these technologies improve efficiency, they can displace traditional manufacturing jobs and require a workforce skilled in new technologies.

- Supply Chain Vulnerabilities: The COVID-19 pandemic highlighted the fragility of global supply chains. Companies are now wary of relying too heavily on overseas manufacturing and are beginning to rethink their supply chain strategies.

- Sustainability Concerns: Consumers are increasingly interested in sustainable products and practices, pressuring manufacturers to adopt more eco-friendly methods.

As industry leaders and HR professionals, understanding these challenges is crucial for developing strategies to remain competitive.

The Role of AI and Workflow Automation

Amid these challenges, companies can leverage artificial intelligence (AI) consulting and workflow automation to streamline processes, reduce costs, and improve product quality. Here are several ways these technologies can impact American manufacturing:

1. Enhancing Efficiency through Automation

Automating routine tasks can lead to significant time and cost savings. AI-powered solutions can analyze workflows and identify bottlenecks, enabling manufacturers to streamline their operations. For example, software tools like n8n can integrate various business processes by automating data transfers between different systems, reducing manual errors, and improving overall efficiency.

Practical Takeaway: Companies should consider investing in workflow automation tools to handle repetitive tasks, allowing employees to focus on higher-value activities such as strategy and innovation.

2. Data-Driven Decision Making

AI can analyze vast amounts of data to identify trends and patterns that humans might overlook. This capability can be particularly beneficial for manufacturers in supply chain management, forecasting demand, and production planning.

Case Example: A manufacturer might utilize predictive analytics to anticipate ingredient shortages or machinery breakdowns, allowing them to make timely decisions that prevent production delays.

Practical Takeaway: Implementing AI-driven analytics tools can provide manufacturers with insights needed to optimize operations and respond to market fluctuations swiftly.

3. Addressing Workforce Challenges

As the manufacturing sector moves toward automation, the demand for skilled labor is shifting. AI consulting can aid companies in identifying necessary skills and implementing training programs to upskill their current workforce.

Industry Insight: A survey conducted by Deloitte found that companies investing in workforce training programs significantly improved employee productivity and engagement, ultimately contributing to better company performance.

Practical Takeaway: Foster a culture of continuous learning and development within the workforce, employing AI solutions to tailor training needs based on individual employee performance and learning styles.

4. Creating More Agile Production Processes

The integration of AI with advanced manufacturing techniques, such as additive manufacturing and smart factories, allows companies to respond to changes in consumer demand more rapidly. By utilizing automation and real-time data monitoring, manufacturers can switch production lines or reallocate resources with greater agility than ever before.

Practical Takeaway: Explore flexible manufacturing systems that can easily adapt to new designs and specifications, reducing lead times and increasing customer satisfaction.

Overcoming Recruitment Challenges in the Manufacturing Sector

As manufacturing evolves, so must recruitment strategies. Attracting talent in this sector requires HR professionals to communicate the dynamic nature of the industry effectively. Here’s how AI consulting can improve recruitment efforts:

1. Using AI to Streamline Hiring Processes

AI-driven recruitment tools can enhance the hiring process by automating candidate screening and leveraging data analytics for more informed hiring decisions. By implementing these tools, HR teams can save time and resources while ensuring they acquire the best talent.

Practical Takeaway: Invest in AI recruitment software to improve the quality of hires and reduce the time-to-fill open positions.

2. Improving Employer Branding

Highlighting the technological advancements and growth opportunities within the manufacturing sector can attract candidates, especially younger generations who prioritize innovation.

Strategies for Improvement:

- Develop content that illustrates your company’s commitment to technology and sustainability.

- Use social media and digital marketing strategies to reach potential candidates and showcase your workplace culture.

3. Focusing on Diversity and Inclusion

American manufacturing companies must prioritize diversity in hiring. Inclusive recruitment practices and the promotion of a diverse workforce lead to more innovative solutions and improved company performance.

Practical Takeaway: Leverage AI tools to help reduce bias in the hiring process, promoting diversity and inclusion as organizational values.

Conclusion: The Path Forward for American Manufacturing

The future of American manufacturing is at a crossroads. As the sector grapples with challenges posed by globalization, advanced technologies, and shifting consumer preferences, the integration of AI consulting and workflow automation presents a formidable opportunity.

By embracing these technologies, manufacturers can not only enhance operational efficiency but also future-proof their organizations against the evolving landscape. Companies that focus on continuous improvement, workforce training, and strategic recruitment will be better positioned to compete globally.

To learn more about how our AI consulting services and automated workflow solutions can elevate your manufacturing operations, contact us today. Together, we can navigate the future of manufacturing and turn challenges into opportunities.

FAQ

1. How can AI improve manufacturing processes?

AI can streamline operations, reduce costs, and enhance product quality by analyzing data and automating tasks.

2. What challenges is American manufacturing currently facing?

Challenges include increased global competition, technological disruption, supply chain vulnerabilities, and sustainability concerns.

3. How can manufacturers attract talent?

By highlighting technology and advancement opportunities through effective employer branding and focusing on diversity.

4. What role does automation play in manufacturing?

Automation enhances efficiency, reduces manual errors, and allows for faster, more agile production processes.

5. Why is workforce training important?

Continuous training improves employee productivity, engagement, and supports the transition to more advanced manufacturing technologies.